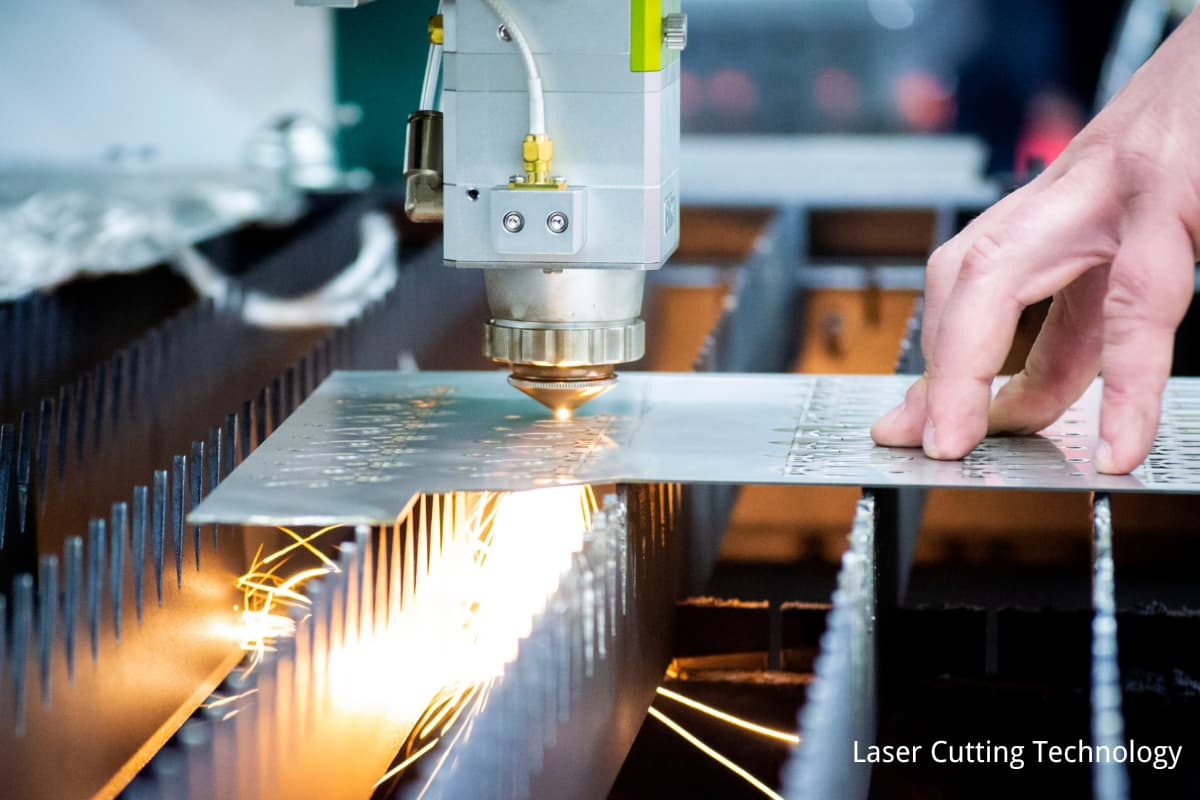

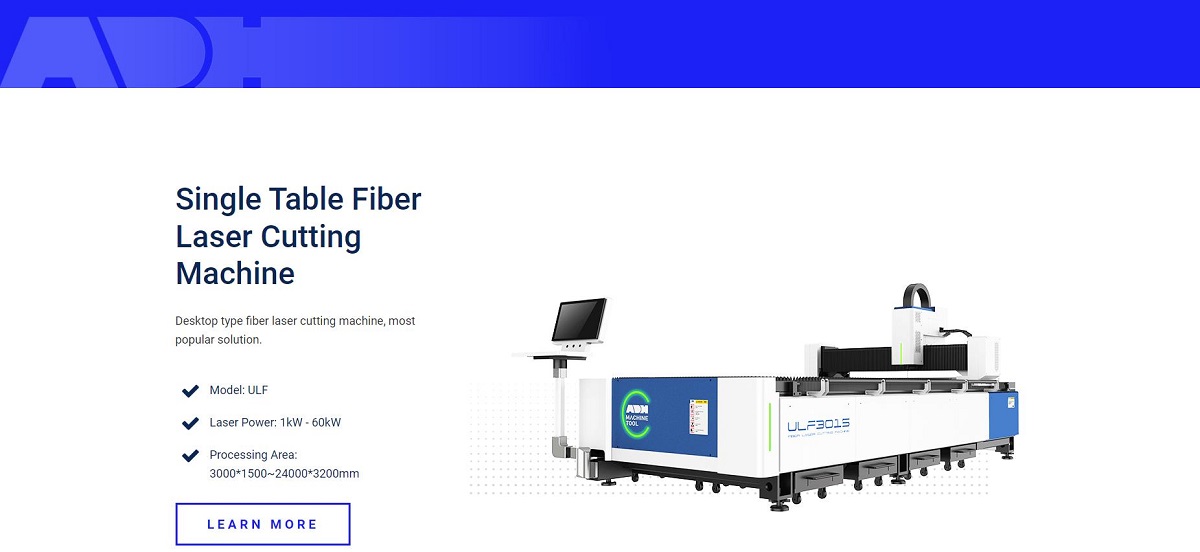

For beginners, we should figure out two questions: What is laser cutting? Why choose laser cutting? Understanding the basic principles, advantages and which one to choose is the first step toward using laser cutting machines correctly. In this article, the basic information of laser cutting machines will be introduced in detail as a way to help the beginners get start quickly. Laser cutting technology utilizes high-power-density laser beams to cut and engrave materials. Focused on the surface of the materials through the optical system, laser beams burn, melt, evaporate, and blow the surface layer of the materials. In this way, the cutting is finished. By virtue of specific capabilities, laser cutting technology emerges as the top choice for modern manufaturing. For the beginners, the first step is to learn and understand laser cutting machines. Therefore, the chapter in the following will introduce the mainstream types and key components of laser cutters so as to help beginners get a deeper understanding of laser cutters. According to the types of lasers, laser cutting machines can be divided into three types, each with its application scenarios. Let's view a video to have an intuitive understanding. CO2 Laser Cutters CO2 laser cutters utilize CO2 gases as the laser medium, suitable for non-metal cutting, such as wood, plastic, glass and paper. The magic machines are famous for high-quality of engraving capability and wide applications. Pros of CO2 laser cutters: Fiber Laser Cutters Using optical lasers as laser medium, fiber laser cutting machines are especially suitable for cutting metal materials such as stainless steel and aluminum. Pros of fiber laser cutters: YAG Laser Cutters The YAG (Yttrium Aluminum Garnet) laser cutting machine uses neodymium-doped yttrium aluminum garnet as the laser medium, suiting for high strength and high hardness processing, such as aerospace components. Prons of YAG laser cutters: Composed by many parts, each component plays an essential role during the cutting. Laser Source As the main component, the laser source is responsible for high-power-density laser beam generation. Commonly, laser sources include CO2 lasers, fiber lasers and YAG lasers. The laser source should be decided on the thickness and type of materials to be processed. Control System The control system manages and coordinates the rest parts of a laser cutting machine. It commonly includes a CNC system which is used to control paths and cutting speed of laser beams precisely. An advanced control system allows for automatic and intelligent operation, improving productivity. Mechanical Bed As a platform to put materials to be cut, a Mechanical bed entails high stability and precision to ensure the materials remain stationary during cutting. The design and material of mechanical bed affects cutting quality significantly. Cutting Head The cutting head is the part where laser beams contact with the materials. It normally includes focusing lenses and a nozzle whic h focuses laser beams on the material surface. Assisted by sprayed gases, the molten and evaporate materials will be blown off the working area. The design and maintenance for cutting heads are vital. Automatic Lubrication Automatic lubrication is used to maintain the best working performance of a laser cutting machine's moving components. Regular lubrication can eliminate wear and tear, prolong the equipment's lifespan, and improve cutting efficiency and accuracy. In summary, laser cutting machines are vital tool for modern manufacturing. The choice of their types and key components directly affects productivity and product quality. Deep understanding of working principles and technology features of laser cutting machines can boost the rapid and high-quality development of manufacturing. It’s vital for beginners to choose the right laser cutting machines. Here are some of key factors which can help beginners to make wise choices. Cutting machines: There are many cutting machines you can choose from, such as CO2 and fiber laser cutting machines. CO2 laser cutting machines utilizing CO2 laser beams are suitable for cutting wood, acrylic, leather and other non-metal materials. They are most used in commercial sectors, with prices ranging from hundreds of dollars to tens of thousands of dollars. Fiber laser cutters are suitable for metal material cutting with high speed, precision and costs, which are usually applied in industrial manufacturing. Cutting thickness: This table summarizes the suitable materials and cutting thickness for different power levels of laser cutters, helping users choose the appropriate equipment based on their specific needs. Budget: Beginners should choose laser cutting machines based on budgets. YAG and CO2 laser cutters, which are relatively cheaper than fiber ones, are more suitable for households and small studios. Application scenarios: For home DIY projects or small craft production, low-power YAG and CO2 laser cutters are sufficient. For commercial or industrial production, high-power CO2 laser cutters and fiber laser cutters should be chosen. You can set up your laser cutting machines in three steps: Unboxing and Assembly: Software Installation: Calibration and Testing: After the steps above, beginners can successfully choose, set and use a laser cutting machine and start a journey to experience laser cutting machines. The laser cutting performance was decided by many parameters, including power, speed, focal length and alignment. Correct settings of parameters can significantly improve cutting quality and efficiency. Power Settings A table to show the power and its corresponding material thickness. Speed Settings Cutting speed is another factors which directly affect cutting quality and efficiency. Focus and Alignment The focal length and alignment are the main factors affecting cutting precision. Focal length adjustment: the focal length should be adjusted according to material thickness so as to make sure laser beams are focused on the material surface. Appropriate focal length can improve cutting efficiency and quality. Laser alignment: laser beams align with cutting paths can avoid offset and errors. Use alignment tools and test cutting samples to ensure the laser beam is accurately aligned. Material Compatibility Different materials react differently to laser cutting, so understanding material compatibility can help us choose the right machines. Understanding of laser cutting parameters and material compatibility enables users to optimize laser cutting procedures, improving cutting quality and efficiency. No matter it is wood, acrylic, metal or fabric, the selection of appropriate laser cutting machines and the setting of their parameters are key elements for success. For beginners, laser cutting machines provide an excellent chance to explore and achieve creative ideas. In the following, I will introduce some simple project ideas and detail step guide to help beginners finish their first laser cutting work. Simple Project Ideas Custom Keychains Customizing a keychain is a simple yet interesting laser cutting project. Although the making process is simple, the production is pragmatic and personalized. You can choose different materials, such as wood and acrylic, to make a unique keychain. Laser cutting machines can precisely cut all kinds of patterns and shapes, enduing every key chain feature. Personalized Coasters Making personalized coasters is another simple project for beginners. You can design all kinds of shapes and patterns for a coaster and cut it through a laser cutting machine.Common materials like wood and acrylic are suitable for laser cutting. Decorative Wall Art As for decorative wall art projects, it’s relatively complicated but can bring a great sense of success. Users can design all kinds of patterns, like flowers, animals or geometrics, and cut them through a laser cutting machine. Wood and acrylic are common materials which allow for smooth cutting edges and precise details. Step-by-Step Project Guide Step one: Designing Your Project Step 2: Preparing the Material Step 3: Executing the Cut Step 4: Finishing the Cut Following the steps above, beginners can finish their first laser cutting project. The machine is not only a powerful tool but an opportunity to activate creation and achieve dreams. This article is for all beginners in the laser cutting field. The detailed introduction of working principles, types, and a step-by-step guide for a laser cutting machine project can help you gain a deeper understanding of the magic machine. Welcome to the world of ADH Machine Tool's laser cutting machines! Our laser cutting machines are like superheroes, effortlessly tackling all kinds of cutting challenges. Whether you're cutting metal sheets or tubes, our machines, such as the Dual-use Fiber Laser Cutting Machine, can complete the task quickly and precisely. Want to know more? Check out our product page and let our laser cutting machines usher you into a new era of efficient cutting! Assault Rifle Scopes,Camo Rifle Scopes,Competition Rifle Scopes,Electronic Rifle Scopes Nantong Dinggo Optical Instrument Co.,Ltd , https://www.riflescopeofficial.comI.Introduction

II.Understanding Laser Cutting Machines

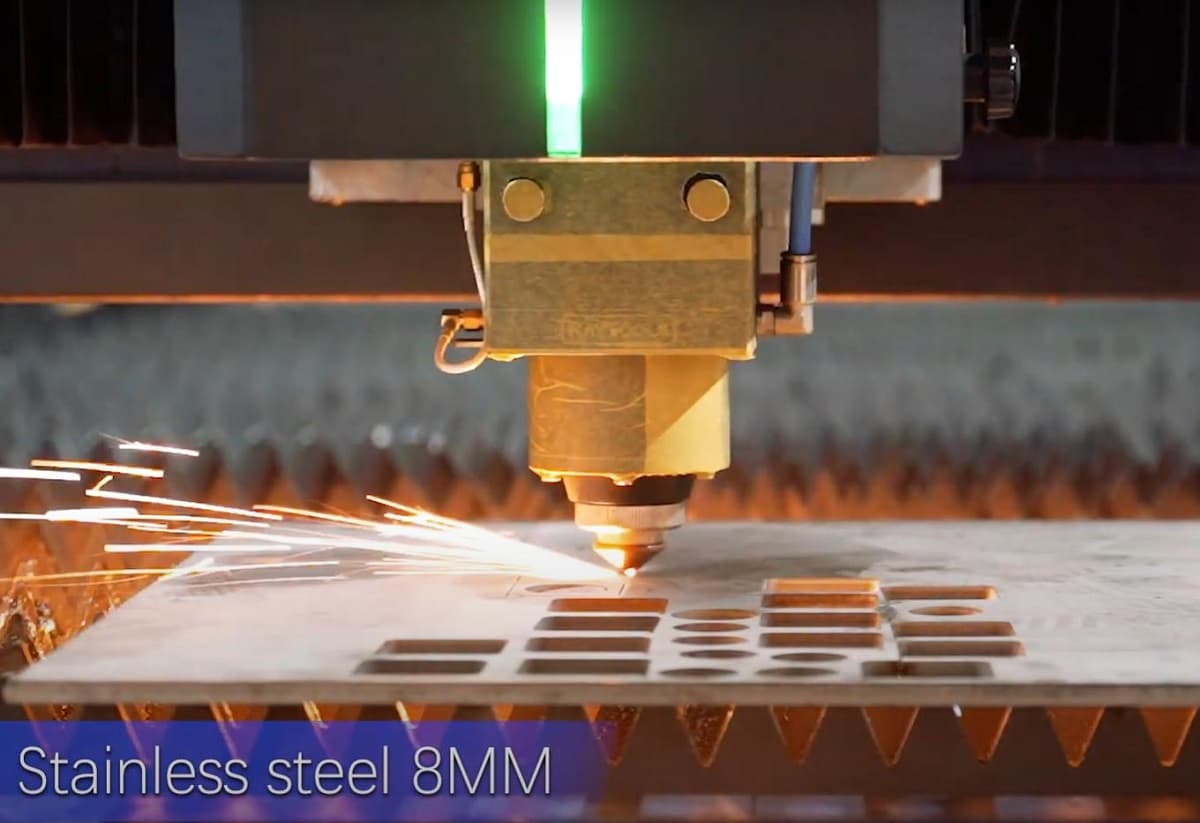

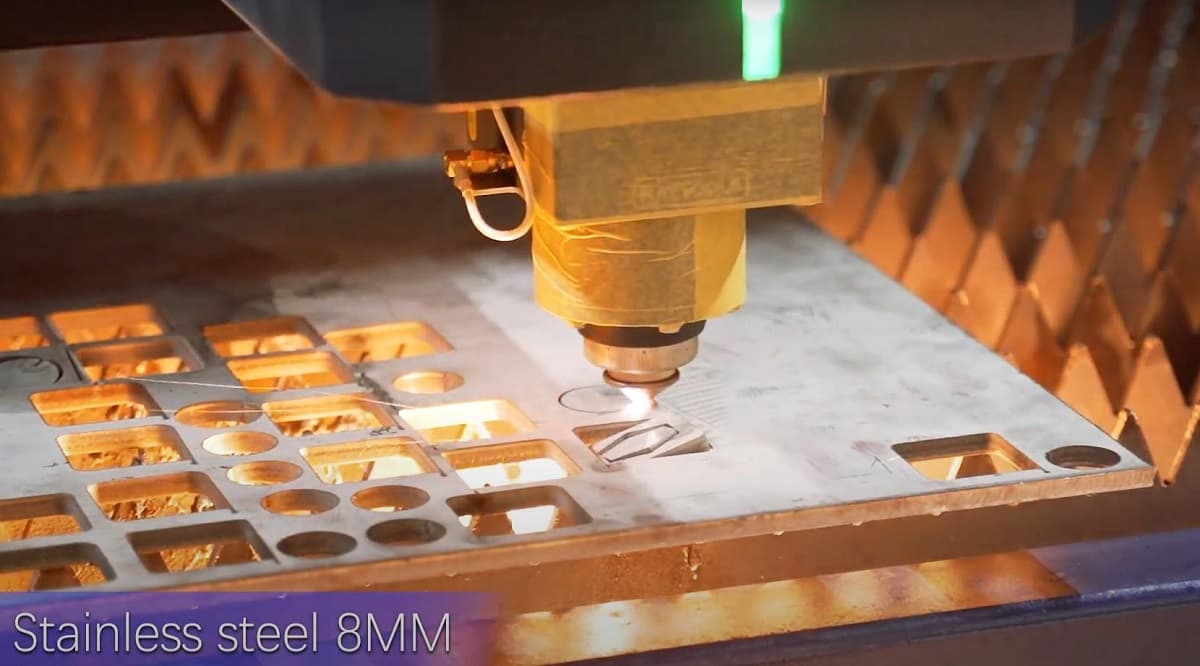

Types of Laser Cutting Machines

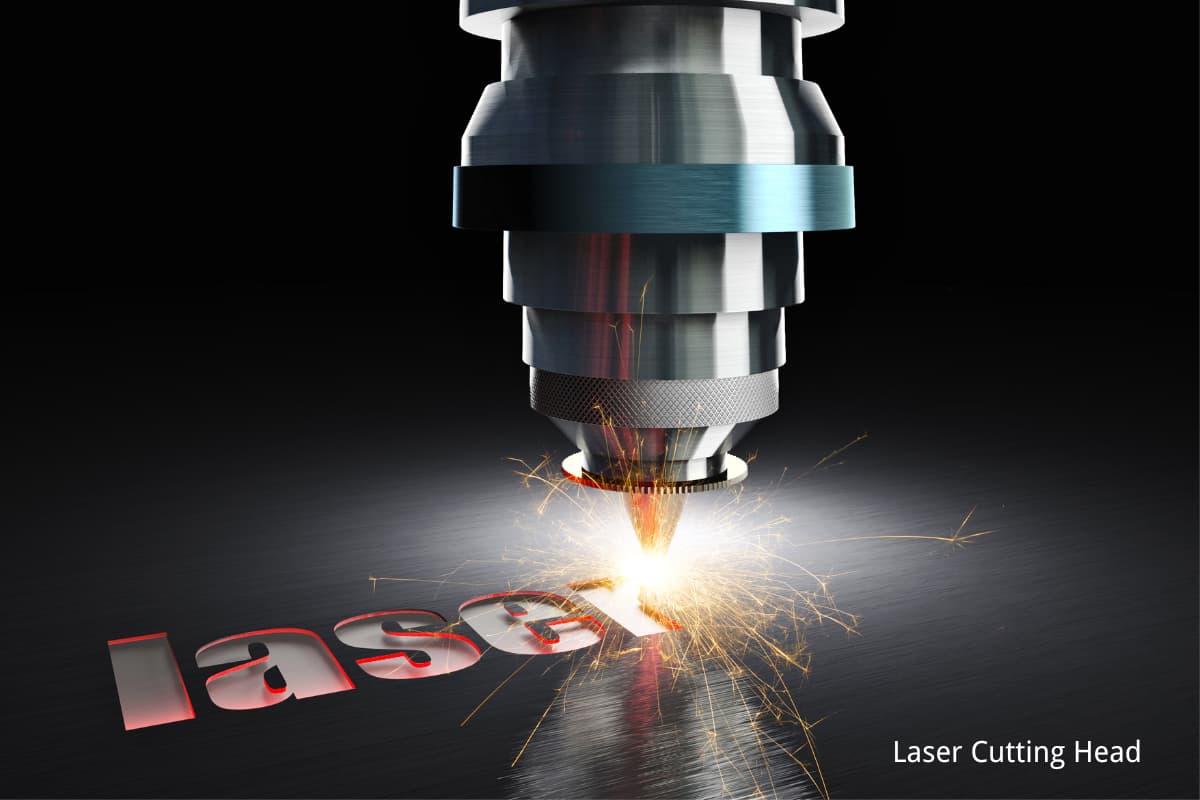

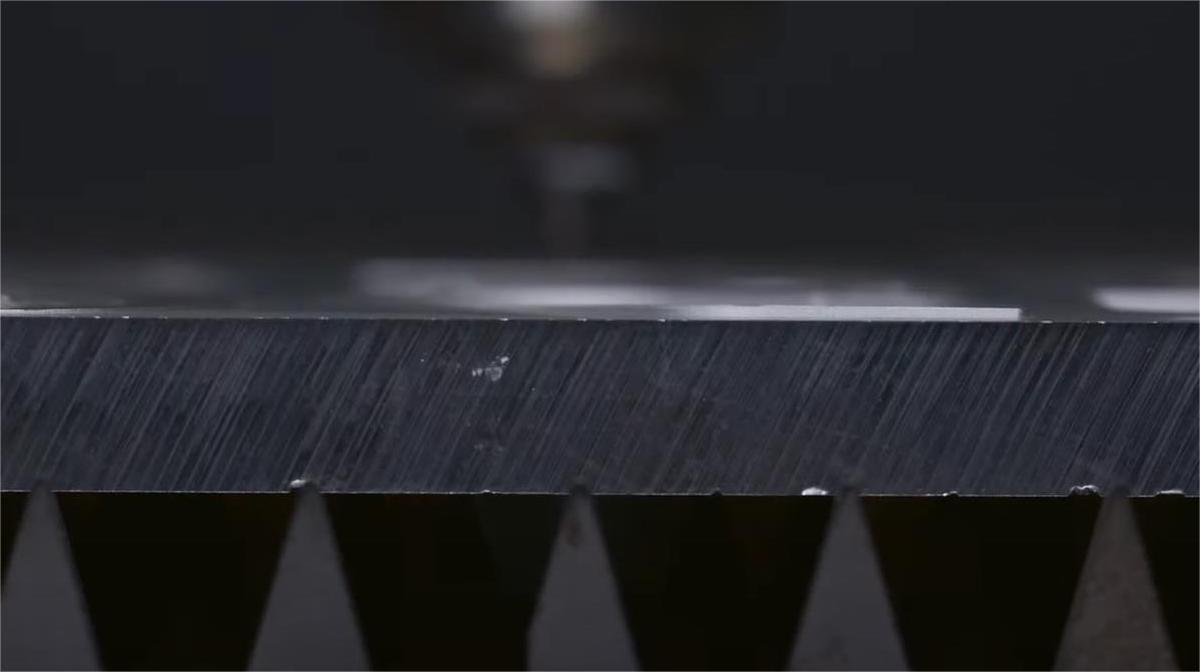

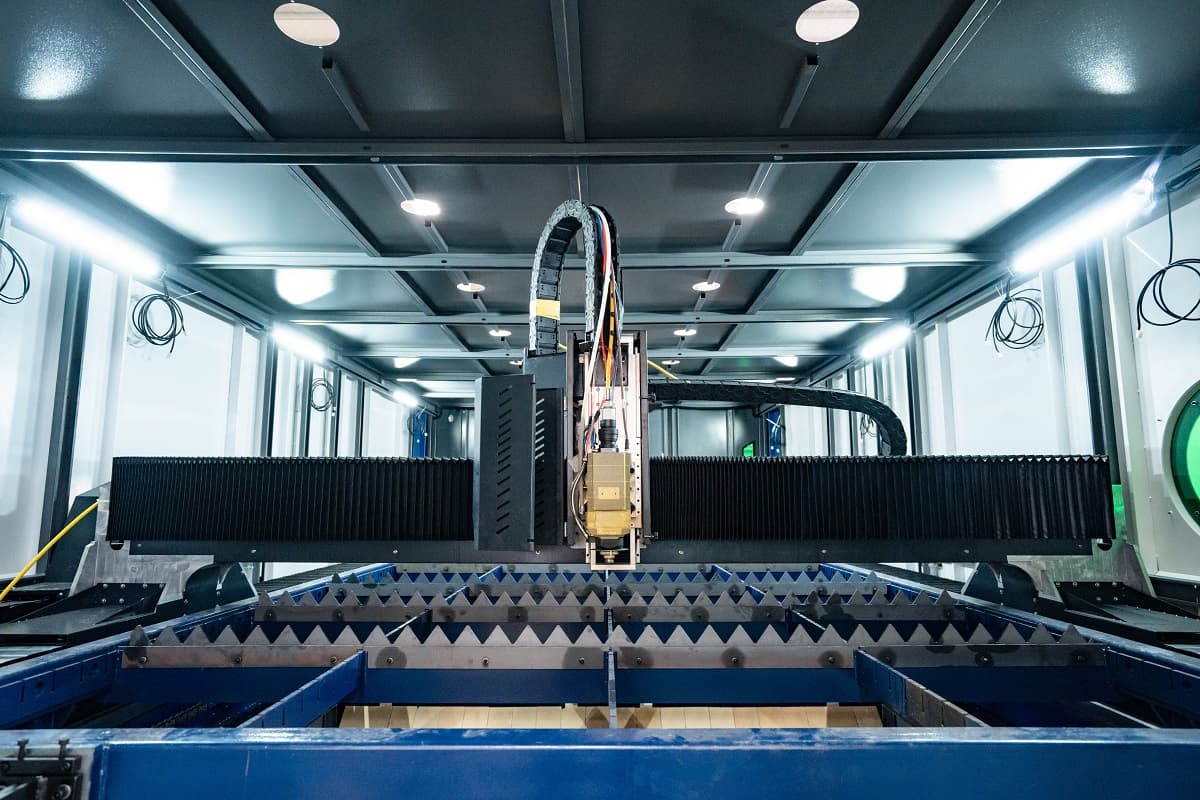

Key Components of a Laser Cutting Machine

III.Getting Started with Laser Cutting

How to Choose the Right Laser Cutting Machine for Beginners

Laser Cutter Power Suitable Materials Cutting Thickness Low Power Laser Cutter (10W-100W) Paper, Thin Plastics Thin Materials Medium Power Laser Cutter (100W-500W) Wood, Acrylic Up to 1/4 inch High Power Laser Cutter (500W-2000W) Metal Materials Up to 1 inch

Setting Up Your Laser Cutting Machine

Laser Cutting Parameters

Laser Cutter Power Applicable Materials Cutting Thickness Low Power Setting (10W-100W) Paper, Thin Plastic Thin Materials Medium Power Setting (100W-500W) Wood, Acrylic Medium Thickness Materials High Power Setting (500W-2000W) Thick Materials, Metal Thick Materials

Speed Setting Applicable Materials & cutting quality Advantages Disadvantages Low-Speed Setting Thick materials, high-precision cutting Ensures laser has enough time to penetrate material It may cause edges to overheat and scorch Medium-Speed Setting Most of materials, regular cutting Balances cutting speed and quality, suitable for most applications None significant, generally well-balanced High-Speed Setting Thin materials, fast cutting Improves production efficiency It may affect cutting precision and edge quality

Material Applicable Laser Type Cutting Power Cutting Speed Tips Wood CO2 laser cutter Medium power Medium speed Adjust power and speed according to wood thickness to avoid scorching and deformation. Acrylic CO2 laser cutter Medium power Medium speed Using low speed settings can achieve smoother edges but requires caution to avoid overheating. Metal Fiber laser cutter high-power CO2 laser cutter High power Low speed Use appropriate cooling systems to prevent laser overheating and material deformation. Fabric CO2 laser cutter Low power High speed Using low power can prevent scorching and ensure smooth cutting edges. IV.Beginner Laser Cutting Projects

V.Conclusion