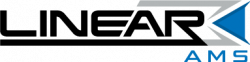

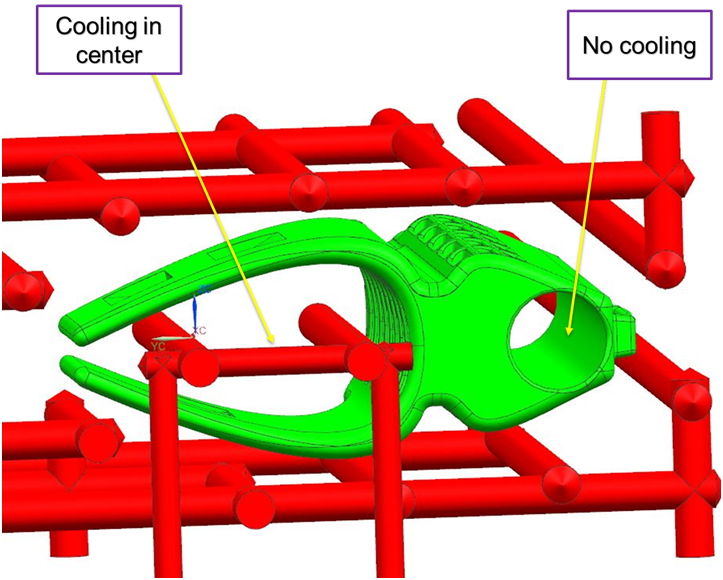

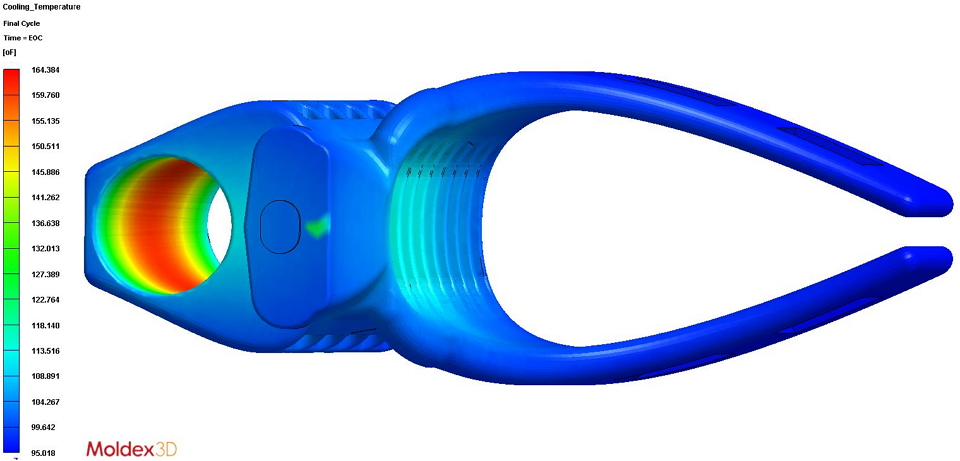

In plastic injection molding, the cooling process is the longest portion, often prolonging the total cycle time. In the supply and demand world, the ability to produce parts faster and more efficiently is always the top priority for the manufacturers. However, conventionally drilled cooling lines in molding tools have many limitations in shortening the cycle time. In order to solve this present issue, Linear AMS decided to propose a new conformal cooling system and utilized Moldex3D to validate the design. In the end, they successfully reduced the cooling cycle and had more confidence while helping their customers solve cooling issues. Utilizing Moldex3D eDesign to design the optimum conformal cooling layout in order to successfully reduce the cooling portion of the cycle time This case features a rifle stock arm brace part. Linear AMS’ long term objective is to design a conformal cooling system to assist customers to reduce cycle times. This project’s specific objectives primarily focused on reducing the cooling portion of the cycle time. First of all, they needed to produce a higher volume of parts, but they were not able to add additional molds and presses into the process. The fill/pack process had been successful prior to Moldex3D’s involvement, so warpage was not an issue. When they utilized Moldex3D to analyze the conventional cooling process (Fig. 1), they found serious heat accumulation in the middle area as well as the shaft (Fig. 2). In order to improve the cooling time, they altered the cooling system that can better conform to the shape of the part (Fig. 3). The cooling in the middle area as well as the shaft was completed and in addition to those areas, new cooling was applied to the outer sides as well.  After the design changes, Linear AMS used Moldex3D eDesign to simulate the revised cooling design. The analysis results of the modified cooling channel design showed a much more uniform temperature distribution (Fig. 4) compared to the original design. As a result, Moldex3D has successfully reduced the cycle time from 112 seconds to 35 seconds. This allowed the customer to produce a higher volume of parts without making additional molds and using additional presses. The benefit of using Moldex3D is making it possible to present the time savings prediction to the customer. From their experience with Moldex3D, Linear AMS has found that the cooling predictions are surprisingly accurate and they now can confidently tell their customers how they can better help them reduce their cycle times (Fig. 6). Pan Concrete Mixer,Electric Concrete Mixer,Mobile Mixing Machine,Cement Mixing Machine Zhengzhou XinFeng machinery manufacturing Co. Ltd , https://www.xfmachinery.com

Executive Summary

Challenges

Solutions

Benefits

Case Study

Fig. 1  Original Cooling Channel Design Â

Fig. 1  Original Cooling Channel Design   Fig. 2  The cooling analysis of the original cooling channel design.

Fig. 2 Â The cooling analysis of the original cooling channel design.

The result indicates heat accumulation in the middle area as well as the shaft. Fig. 3 Â The revised cooling channel design

Fig. 3 Â The revised cooling channel design Fig. 4 Â The analysis results of the revised cooling channel design. The temperature distribution is much more uniform.

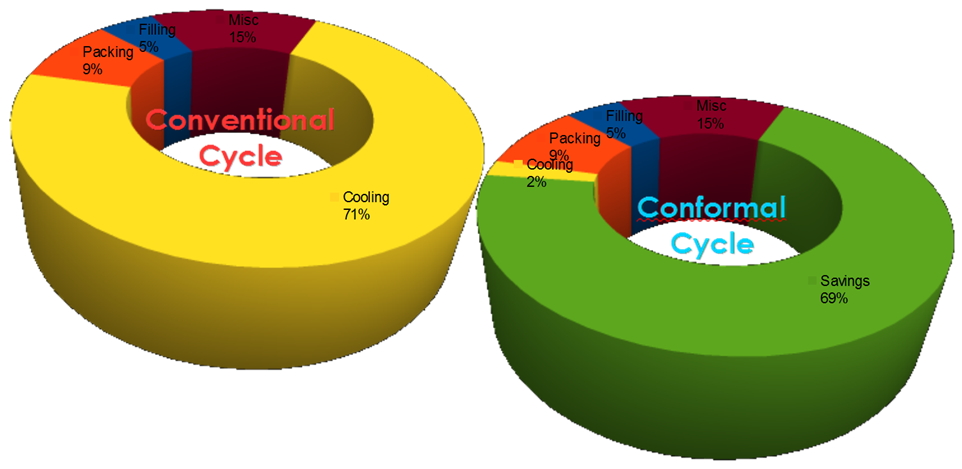

Fig. 4 Â The analysis results of the revised cooling channel design. The temperature distribution is much more uniform. Fig. 5 The breakdown of savings in this case: the reduction in the cooling cycle

Fig. 5 The breakdown of savings in this case: the reduction in the cooling cycle

has translated to 69% in the manufacture cost.Results

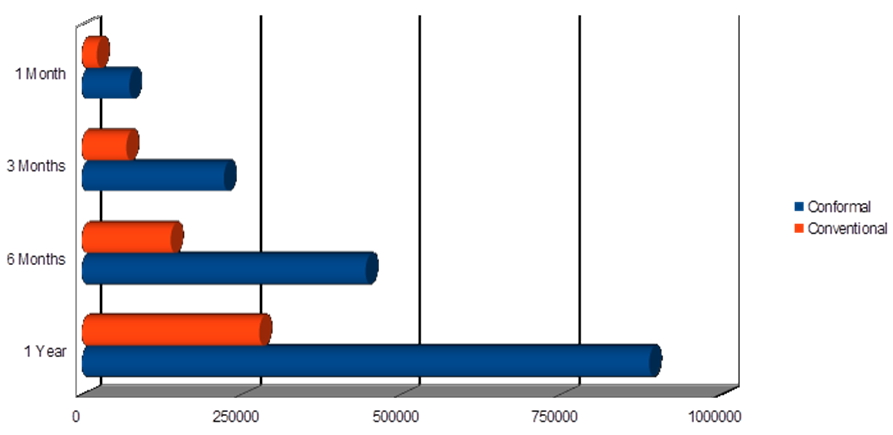

Fig. 6 Â The difference a savings of 77 seconds per shot can make over the course of a year

Fig. 6 Â The difference a savings of 77 seconds per shot can make over the course of a year

Linear AMS Utilizes Moldex3D Conformal Cooling Analysis to Reduce 69% Cooling Time

Customer Profile